RGB, CMYK, and Pantone – what’s the difference? You may know that these are different ways that you can select colours, but what do they really mean? The different colour modes serve different functions, so it’s important to know when to use them.

In this post, we’ll talk about each colour mode, and what the difference between them is. Read on to learn more!

CMYK

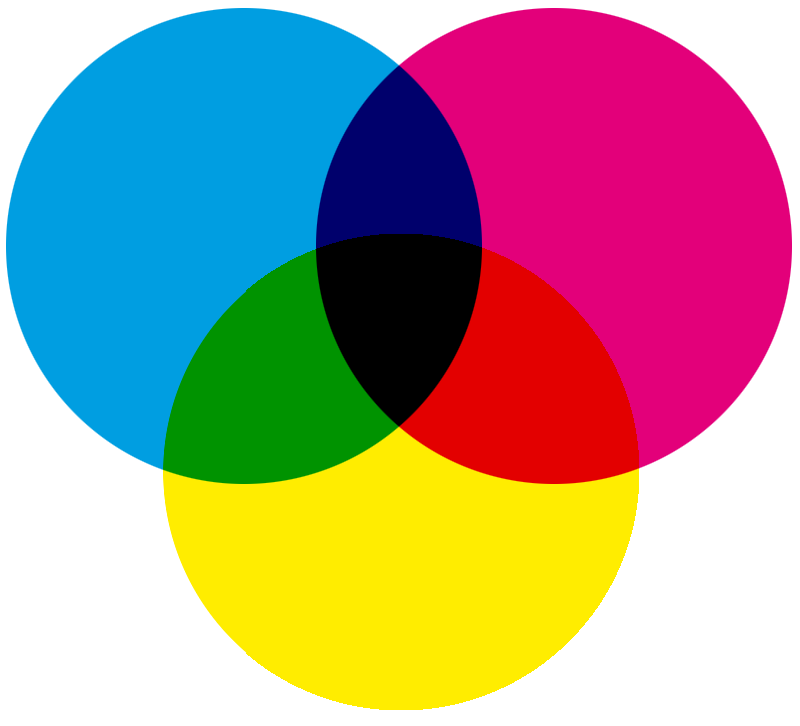

First, we’ll talk about CMYK. CMYK stands for Cyan, Magenta, Yellow, and Key. By subtracting light where these colours overlap, new colours can be made.

The resulting colour is the visible spectrum of wavelengths that did not get subtracted. By assigning each letter a percent value, you can create different colours.

Products printed with CMYK use dots of each colour that overlap to make a solid tone.

RGB

By contrast, RGB is the direct opposite to CMYK. CMYK uses a subtractive model, whereas RGB uses an additive model.

The RGB colour model relies on the addition of light to Red, Green, and Blue to create new colours. As each colour is assigned a value, new colours are made.

Pantone

The final colour mode is Pantone, or the Pantone Matching System (PMS).

Pantone is a company that uses the CMYK model to create a spot colour. Unlike CMYK, spot colours created by Pantone are solid and do not feature multiple small dots.

As a result, Pantone colours can go beyond the spectrum of CMYK colours to include metallic ones as well.

When to use the different colour modes

We’ve established the different colour modes, but how would you decide which to use?

CMYK is best for printing things at home, or on a budget. CMYK printing may produce different results based on individual printers, so colour consistency can vary.

RGB was created for digital and electronic colouring like phones, TVs, and websites. The colours used in RGB may look different across devices, so they aren’t the best for consistent colours.

Pantone colours will always produce the most sharp and accurate colours. The PMS is best to use when screen printing, textile/product manufacturing, or in cases where colour accuracy is important. While these are accurate colours, they can also be more expensive since each colour must be mixed individually.

How do we use the different colour modes at LeKAC?

At LeKAC, whether you have your own design or need a helping hand, we’re with you every step of the way!

Our design specialists use CMYK to design your packaging since most printers print in the four colour process, so the colours in print are more accurate.

Then, we convert these colours using the PMS before sending your packaging into production, so you get the most accurate colour in person.

Customer service is king at LeKAC, and that’s why multiple quality control checks are performed throughout the printing and production process to make sure the colours are exactly the way you envisioned them!

Interested in creating custom packaging with LeKAC? Contact us today to learn more!